Introducing the High-Speed Induction Sealer: SealerOn™ 3000

The SealerOn™ 3000 is the high-speed induction sealer designed for efficiency, adaptability, and precision—far more than just another sealing machine. Whether used in food production, pharmaceuticals, nutraceuticals, or cosmetics, it offers unmatched versatility. As demand grows for tamper-evident packaging and faster throughput, businesses are turning to smarter automation solutions. The SealerOn™ 3000 meets those needs on every level.

Designed for Industrial Throughput

In today’s competitive manufacturing environment, speed and reliability are essential. Therefore, the SealerOn™ 3000 was developed to meet the exacting needs of high-volume production lines. As a result, this high-speed induction sealer supports continuous, non-contact sealing—ideal for operations requiring minimal downtime and consistent output.

Moreover, with an advanced induction coil and smart sensor integration, it ensures that every container receives a uniform, tamper-evident seal, regardless of size or cap style. In fact, whether sealing flat caps, sport caps, or specialty closures, the machine adjusts with ease, offering true plug-and-play performance.

Unmatched Versatility in a Compact Design

Unlike many bulky industrial machines, the SealerOn™ 3000 has a compact footprint that fits neatly into existing production spaces. However, don’t be fooled by its size—this high-speed induction sealer still delivers power and precision at scale.

Furthermore, it accommodates a wide range of containers, from small supplement bottles to larger cosmetic jars. Consequently, it becomes an ideal choice for manufacturers managing a diverse product portfolio. Additionally, switching between container types requires no retooling, thanks to its modular design.

Smart Features With This Efficient Induction Sealing Machine

The SealerOn™ 3000 isn’t just fast—it’s smart. This high-speed induction sealer comes with features that enhance usability and reduce operational complexity:

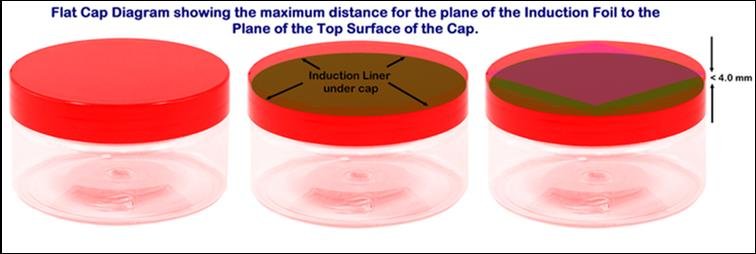

- Universal Flat Cap Induction Sealing Head: allows operation with flat caps ranging from 20 mm to 120 mm, without frequent adjustments to the sealing head angles.

- Tool-free height adjustment: Accommodate different container heights without manual tools.

- Touchscreen controls: Intuitive interface for quick setup and process monitoring.

- Built-in diagnostics: Real-time alerts and system checks minimize the risk of faulty seals.

- Auto-shutoff and safety sensors: Ensure operator safety and equipment longevity.

Each of these features contributes to shorter changeover times and improved operational efficiency, which translates into better ROI for your business.

The High-Speed Induction Sealer Built to Scale With Your Operation

Whether you’re a growing mid-sized business or an established enterprise, scalability is essential. That’s why the SealerOn™ 3000 grows alongside your operational needs. Specifically, this high-speed induction sealer integrates seamlessly with automated conveyors and bottle handling systems. As a result, as output increases, the SealerOn™ 3000 remains a dependable cornerstone of the sealing process.

In addition, it supports remote diagnostics and maintenance, making it easier to remain operational with minimal interruption. As industries increasingly shift toward remote operation and centralized monitoring, this feature becomes even more valuable.

Reliability That Reduces Waste and Downtime

Every minute of downtime in a production line is costly. Therefore, reliability is built into every component of the SealerOn™ 3000. Its solid-state induction generator delivers consistent sealing power, effectively reducing the likelihood of defective products due to under- or over-sealing.

Additionally, this high-speed induction sealer includes integrated cooling systems to protect both the machine and the materials. With better thermal management, it allows for longer shifts without performance loss. In the end, this is the kind of reliability that builds trust with your end users.

A Green Choice for Sustainable Packaging

Today’s manufacturers are increasingly looking for environmentally friendly solutions. The SealerOn™ 3000 contributes to sustainability in several ways. Firstly, it reduces the need for shrink bands or extra tamper-evident labels by sealing directly onto the induction liner, which cuts down on plastic waste and packaging materials.

Secondly, the high-efficiency design of this high-speed induction sealer reduces power consumption compared to traditional sealing systems. As a result, less energy use translates to lower utility costs and a smaller carbon footprint.

Easy Integration Into Existing Lines

Whether you’re automating from scratch or upgrading an old system, integration can often be a pain point. However, the SealerOn™ 3000 makes it painless. Designed for compatibility with most standard conveyors and packaging lines, this high-speed induction sealer installs quickly and works flawlessly with upstream and downstream systems.

There’s no need to overhaul your setup—this machine fits in and performs from day one. Furthermore, with optional bottle spacing wheels and infeed guides, it adapts smoothly to your unique production needs.

Global Support and Training

When you invest in the SealerOn™ 3000, you get more than just a high-speed induction sealer—you get comprehensive support. SealerOn™ provides global service, installation, and training. Our team ensures you get the most from your investment from day one.

We offer remote training sessions, step-by-step setup guides, and ongoing technical assistance. That way, your team feels confident operating and maintaining the equipment. Our goal is to empower your staff, minimize downtime, and maximize uptime.

Applications Across Industries with This Fast Induction Sealer

The SealerOn™ 3000 serves a wide array of industries:

- Food & Beverage: Ensure tamper-proof packaging for sauces, condiments, oils, and drinks.

- Pharmaceuticals: Achieve secure seals for tablets, capsules, and liquid medications.

- Nutraceuticals: Handle a range of plastic and glass containers for supplements.

- Cosmetics & Personal Care: Seal creams, lotions, and oils with style and integrity.

In each case, this high-speed induction sealer offers precision, speed, and flexibility—traits essential for maintaining brand integrity and compliance.

Why Choose the SealerOn™ 3000?

Still wondering if this is the right choice? Here are the top reasons to choose this high-speed induction sealer:

- Fast, continuous sealing for high-output operations

- Minimal maintenance and maximum uptime

- Support for diverse container and cap types

- Eco-friendly design with energy-saving components

- Seamless line integration

- Global service and remote diagnostics

When you choose the SealerOn™ 3000, you’re investing in a proven, scalable solution trusted by manufacturers worldwide.

Final Thoughts

In an age where speed, precision, and adaptability are everything, the SealerOn™ 3000 stands out as the ultimate high-speed induction sealer. Built with the needs of real manufacturers in mind, it brings together cutting-edge technology, operational simplicity, and long-term reliability.

Whether you’re launching a new product line or upgrading your sealing equipment, the SealerOn™ 3000 provides the performance edge your business needs. Don’t settle for average sealing—upgrade to a solution that delivers speed and consistency at scale.

Ready to seal the future?

Contact us today to learn how the SealerOn™ 3000 can transform your production line.