MeRo Induction Sealer Machine Range

We believe there is no better value medium priced “High End” Induction Sealing Equipment. There are unique features to allow process validation and adjustable width sealing head tunnels are available.

MeRo Induction Sealer Machines feature:

MeRo Induction Sealer Machines feature:

- An Air cooled system (Absolutely no need to water cool the induction head).

- Compact construction for easy integration into the filling line.

- High power efficiency thanks to the configuration of the power circuits and the use of IGBT modules.

- Sinusoidal output waveform (Not Square or chopped).

- Constant and Precise Output power due to the configuration of the regulation circuits.

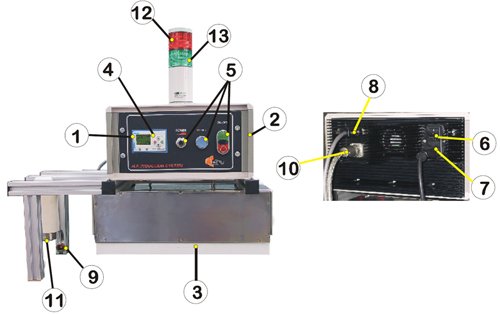

- Easy to use controls that display operating parameters and alarm signals.

- Remote control Start-Stop interface.

- Power variation monitor which can be set by the user to activate an alarm.

- Manufactured in accordance with EN-60204-1 standards, Electromagnetic (EMC) compatibility in accordance with EN-5511 and EN50082-2 standards.

- Motorized height adjustment

- Set-Up Validation providing an Energy absorbed reading- A key advantage over Nearly Every other make

Depending on the range of product and cap, lid, closure shapes, different sealing heads can be supplied.

Options include:

- Missing Foil Detection with Bottle Eject Mechanism or Signal

- Bottle Accumulation Detection to avoid the situation where bottles are stalled under the active sealing head.

- Pressurized Cabinet version to work in dangerous areas.

- Fieldbus connection to the production process ASI/PROFIBUS/CAM OPEN/DEVICE NET

- Integration of power regulation proportional to the speed of the conveyor via feedback from your existing conveyor’s speed controller. This is another key advantage that MeRo are able to offer over nearly other make.