Induction Sealer

The MeRo 2KW Air Cooled unit is a reliable racehorse with standard features that many quote as confusingly priced options. It is what we call the medium priced high end machine.

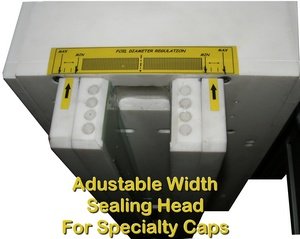

The machine has a Motorised Height Adjustment, Missing Foil Detection, and Bottle Accumulation Detection. It also has an energy trasnferred reading for process validation. This unit can be supplied with a flat sealing head or an ADJUSTABLE WIDTH tunnel sealing head.

Really built in Europe(Italy); not simply assembled with Chinese circuit boards and parts and then sold as a western made machine.

The MeRo equipment comes from the MeRo family of power electronics that includes Coronatreater that go well beyond 75KW !!; so you can trust that you are dealing with equipment manufactured by a company that knows how to build and handle power electronics.

Electrical and Mechanical Specifications*

Supply voltage 3×380 V. 50 Hz three-phase

- MAXIMUM DRAWN POWER: 2,2 KVA

- MAXIMUM OUTPUT POWER: 2 KW

- WORKING FREQUENCY:30 – 50kHz

- AMBIENT TEMPERATURE : 0°C..+40°C (-25°..+70° transport) (-25°..+55° storage)

- RELATIVE HUMIDITY : <85%

- PROTECTION : IP20 STANDARD

- CERTIFICATION : EC (LOW VOLTAGE)

- DIMENSIONS GENERATOR : Dimensions height 600mm, length 365mm, depth 460mm. Weight 55 Kg

*Subject to Change

Typical Application Configuration:

CONVEYOR SPEED: up to 30 m/min;

FOIL SIZE: 35 mm;

CAP SIZE: 55 mm ext. diameter;

CAP STYLE: flip top screw cap (see drawing);

BOTTLE MATERIAL: Plastic