Induction Sealers

To understand this question of the sealing head shape we must first understand how an induction seal is achieved.

The sealing head is the part of the machine that is placed over the path of the product cap/lid. Within the sealing head is usually long oval shaped coils of thick wire that carry high current that changes direction many thousands of times a second. This creates a magnetic field at right angles to the coil that also changes direction many thousands of times a second. The magnetic field can travel through air and plastic but it does get weaker as it travels away from the coils that generated the magnetic field. When the magnetic field comes across metal, it will act to generate current in the metal.

In the case of the heat sealing machine, it waits for a product that has a metal laminated foil in its cap. The magnetic field from the sealing head acts to generate current in the laminated foil and the laminated foil gets hot. Laminated to the foil is a layer that will melt or become “wet” with heat. When the product has completely passed from under the induction machine the foil will begin to cool and the layer that became “wet” will set to bond the laminated foil across the opening of the product.

From the above “theory” it can be understood that the sealing of a bottle or product using induction machines will depend on how long the product is under the magnetic field and how close it gets to that origins of the magnetic field.

There are two distinct shapes of sealing heads for cap sealers being Flat profile and Tunnel profile sealing heads.

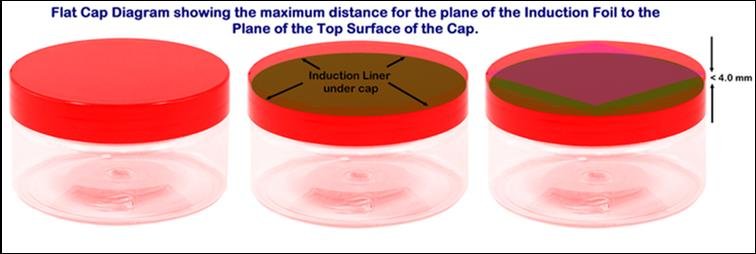

The Flat profile sealing head is suitable for “Standard Flat Caps” . A “Flat Cap”, generally speaking, refers to a cap where the plane of the induction liner is within 4.0 mm of the plane of the Cap’s top surface.

The Tunnel profile sealing head is suitable for “Specialty Caps”. A Tunnel Induction Sealing Head lets you seal caps where the foil sits a distance greater than say 4 mm from the top surface of the cap; this is often the case with twist top spouts, flip top lids, sports drink caps, sipper caps or shaker caps.

The Tunnel sealing head concentrates the magnetic field to an area within the tunnel profile and hence provides stronger magnetic fields over a generally smaller width path for the products passing underneath. A Tunnel sealing head also allows the coils within the sealing head to have a path lower than the top of the product caps. This brings the magnetic field closer to the plane of the foil within “specialty caps”. The drawback to this Tunnel profile sealing head is that it is usually not very good for large caps and it does limit the range of cap sizes that can be efficiently sealed. There is a small exception to this rule with the MeRo™ brand induction sealer with an adjustable width tunnel profile. This machine can typically cater for a range of specialty caps with an adjustment of 30mm which would mean a typical cap diameter range of 30mm to 60mm could be very efficiently sealed.

Efficient cap sealing means that less time is needed under the sealing head and hence higher production speed is possible.

A Flat profile sealing head will allow for a greater range of cap sizes and even allows for that Sealing head to be placed at an angle across the product’s path to achieve sealing of cap diameters that are even wider than the coil winding pattern within the sealing head. It is quite possible to have a Flat profile sealing head that can seal caps from 30mm to 110mm wide. The trade-off for the versatility of this profile sealing head on a heat sealing head is lower speed throughput and an inability to seal specialty caps.